Resembling the shape of a crocodile mouth, a stapler sinks its teeth into a 10-sheets of paper, pierce through its fibrous tissue, and deforms its metal fangs into hooks. Efficient, low-energy, but also low-precision, staplers are the staples of office supplies. Without it, papers are just helplessly scattered across your desk.

Today, we dive into the design of staplers, an idea of such a device came as early as 1866 by the Novelty Manufacturing Company as requested by King Louis XV in France. Sick of gluing and sewing individual pages together, the first stapler used golden staples to puncture and tack papers together, but only held one staple at a time. Numerous iterations of improvement followed the first idea, until the common office tool is born.

Observations:

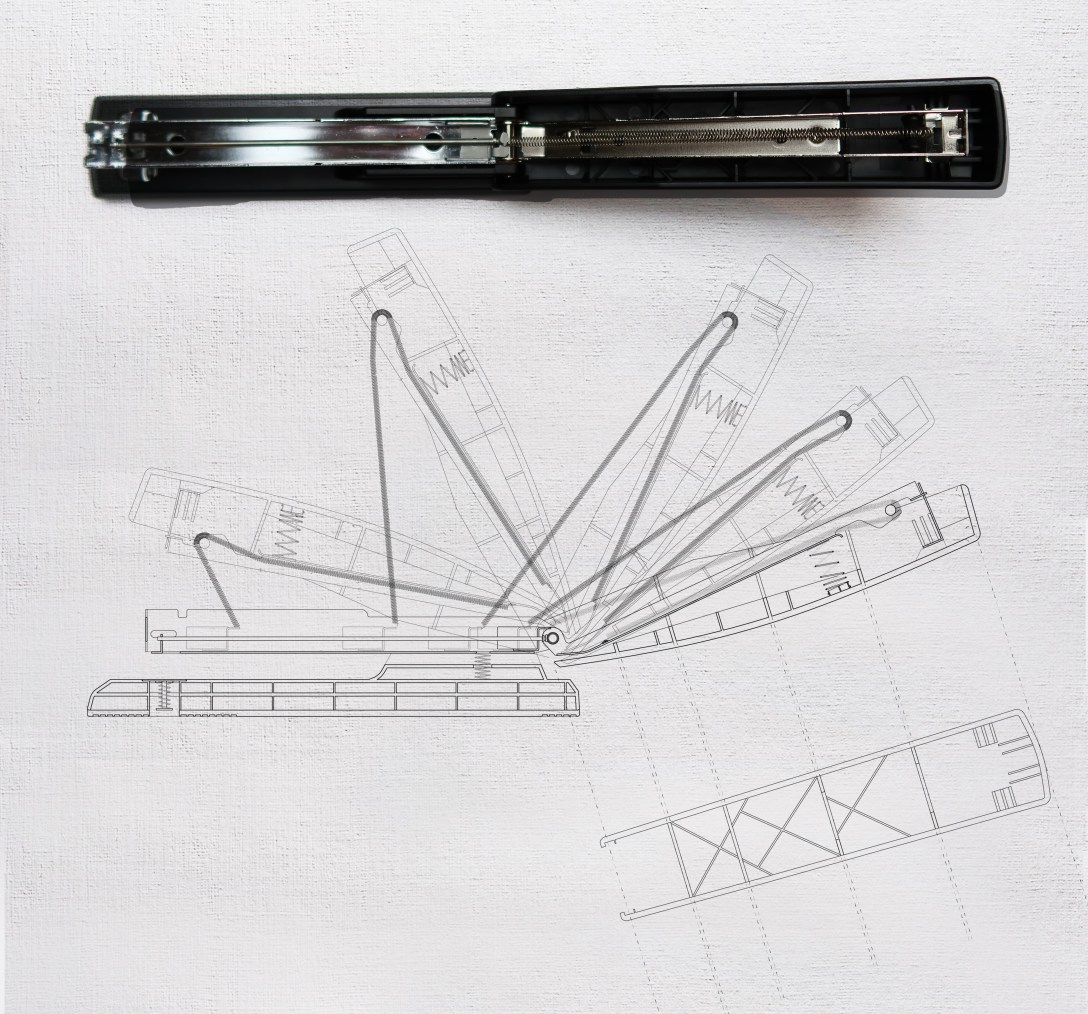

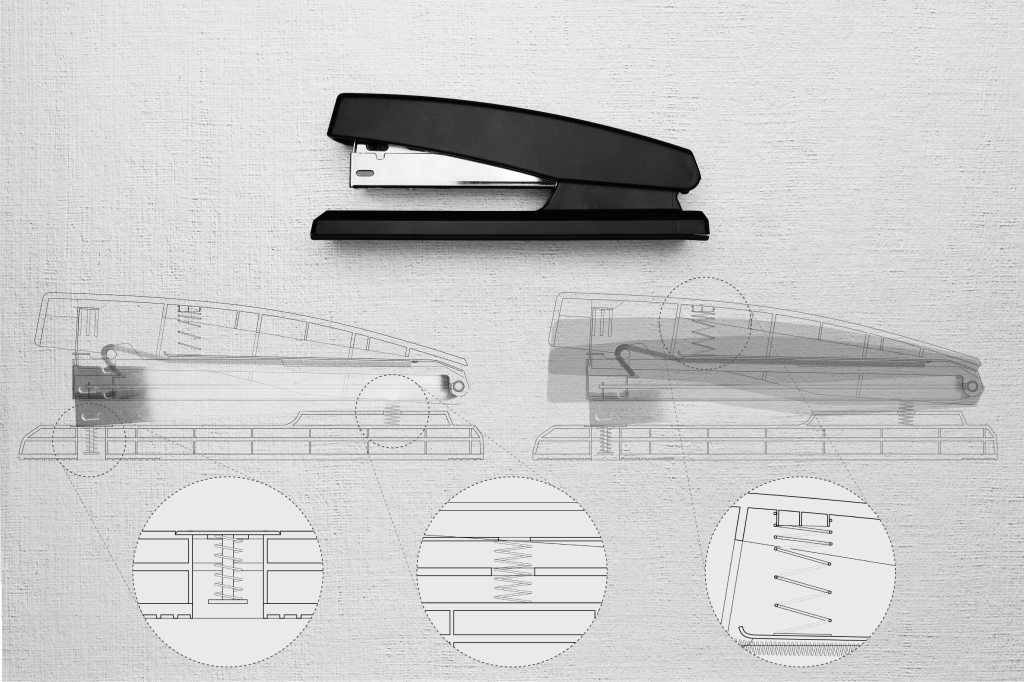

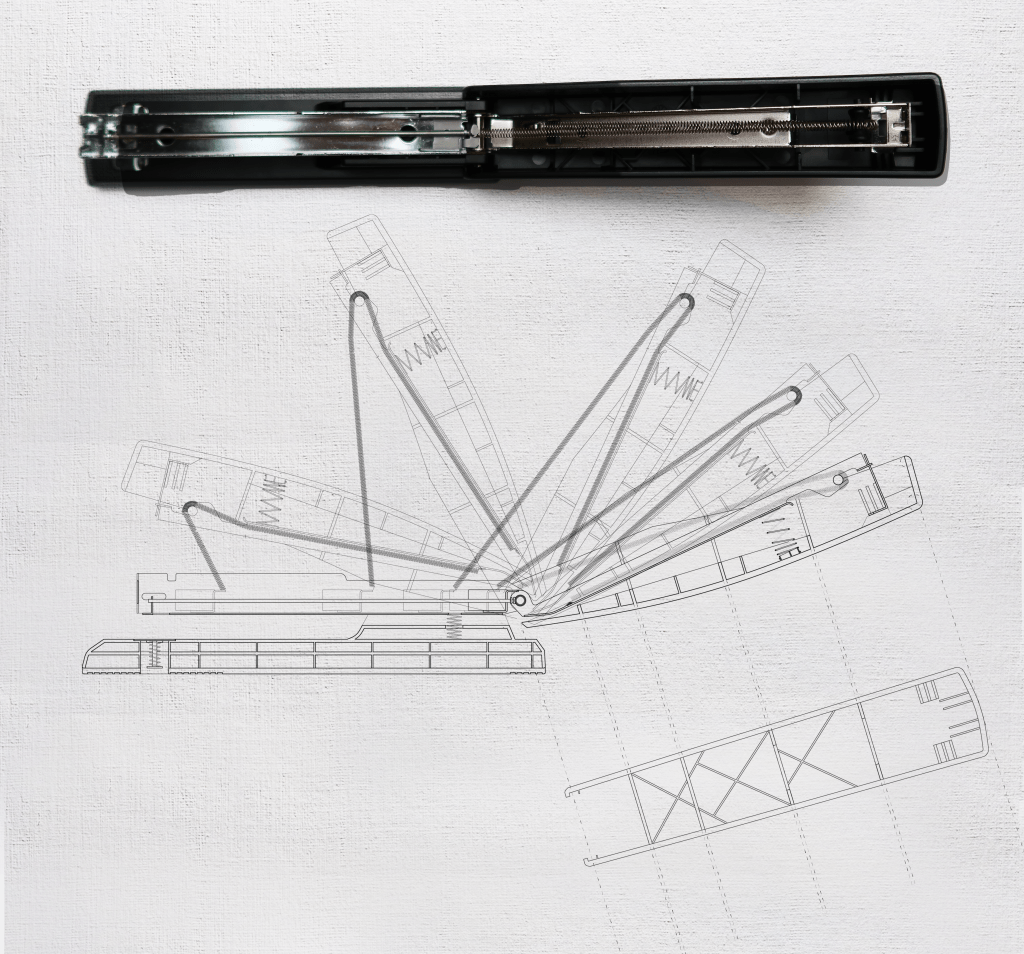

Operates essentially as a hinge mechanism: force applied on the top component, pushes a metal tongue down to deform a thin 500 μm zinc-plated metal wire from a C-shape to fold inward or outward, using the bottom metal plate (anvil) as the mould/guide.

Binds two layers of sheet materials stacked on top of each other, or binding a sheet to a host, or connecting two sheets.

In its interiors: one hinge and four springs, 2 springs work together to perform 2 stages of the compression process, 1 long spring for pushing against and loading the staples, and 1 spring at the bottom component for adjusting the anvil.

Signifiers come in the angling of the mouth, opening wide for paper intake; also the curvature of the top plastic component, suggesting hand placement

Can afford to have changeable anvil, but the pin that pushes up the plate to be rotated is at the bottom, probably not as obvious.

Exteriors: a rubber mat attached at the bottom for anti-slip when stapling on a surface. Though, it would be interesting to see how many people hold the staplers upward and squeeze, instead of laying it on a flat surface and press. One might do the former as having the full mechanism in your hand might seem like you have more control over its placement. Yet, most staples would work best when it is being pressed, as the straight up-down motion decreases the likelihood of messing up when the metal tongue dispenses one of the staples from its strip.

Analysis:

The design intent has historically been to bind sheets/pages together, into leaflets, booklets, or to mount a sheet onto a host, such as posters on walls. Aside from the typical office stapler, stapler variations include those with deeper reach into the paper feed, no base plate for mounting, longer levers, and an electric mechanism.

- Deforming wire with pressure to a specific shape with anvil

- Fastening at points, thin materials; could fasten along a seam, not effectively and efficiently

- Hinge mechanism, limiting depth unless metal portion rotated (see booklet stapler)

- Handheld and mobile

- Lack of visibility on placement, and lack of prediction of placement due to opaque plastic and metal material

Decontextualization:

- Placing grips, or pull handles? Attaching grips on the side of mountains for mountain climbing?

- Replace stitching on clothing or any connections between fabrics, more efficient way of building temporary fabric shelters? Or protective clothing?

- Any cases where the need of “latching” on to something, or tacking something together at a point is applicable for this tool

Redesign:

- Add precision: make staplers out of fully transparent materials such as plexi-glass, glass, resin, to show positioning of staple and the decreasing inventory of it

- Keeping opaque materials but adding exterior marking that assist in locating the placement of staple

Dear Staplers, your anvil looks like an imprint of someone’s two-front teeth. “

Inquisitive Biter